The goal is to transform the campus into a high-volume hub for electric vehicle (EV) manufacturing, making it the first time a full-line automaker will produce passenger EVs in Canada for the North American market. The revamped Oakville Electric Vehicle Complex will include a new on-site battery plant and will begin retooling and modernizing in the second quarter of 2024. The facility will assemble battery packs on-site using components from BlueOval SK Battery Park in Kentucky. This move is part of Ford’s larger Ford+ transformation plan and commitment to sustainability.

Ford’s Investment in Oakville Assembly Complex: The Future of Electric Vehicle Manufacturing

Ford Motor Company’s recent investment of C$1.8 billion in its Oakville Assembly Complex marks a major milestone in the automotive industry. The decision to transform the plant into a high-volume hub for electric vehicle (EV) manufacturing is a testament to Ford’s commitment to innovation, sustainability, and the future of the automotive industry.

The Oakville Electric Vehicle Complex will be the first full-line automaker in Canada to produce passenger EVs for the North American market. With this transformation, the plant will feature a new on-site battery plant that will utilize cells and arrays from BlueOval SK Battery Park in Kentucky. Workers at the Oakville facility will assemble battery packs that will then be installed in vehicles assembled on-site.

This investment is a crucial step for Ford as it aims to stay competitive in the EV market. The company has already announced plans to create an all-new EV manufacturing ecosystem in West Tennessee, called BlueOval City, which will be the home of a battery plant and the future home of Ford’s next-generation EV pickup. These investments reflect Ford’s commitment to sustainable mobility and the transition to a low-carbon future.

The Impact of Ford’s Investment on the Canadian Auto Industry and Economy

Ford’s investment in the Oakville Assembly Complex is set to have a significant impact on the Canadian auto industry and economy. As the first full-line automaker to produce passenger EVs in Canada for the North American market, this investment will create new jobs and bring new expertise to the country’s automotive industry.

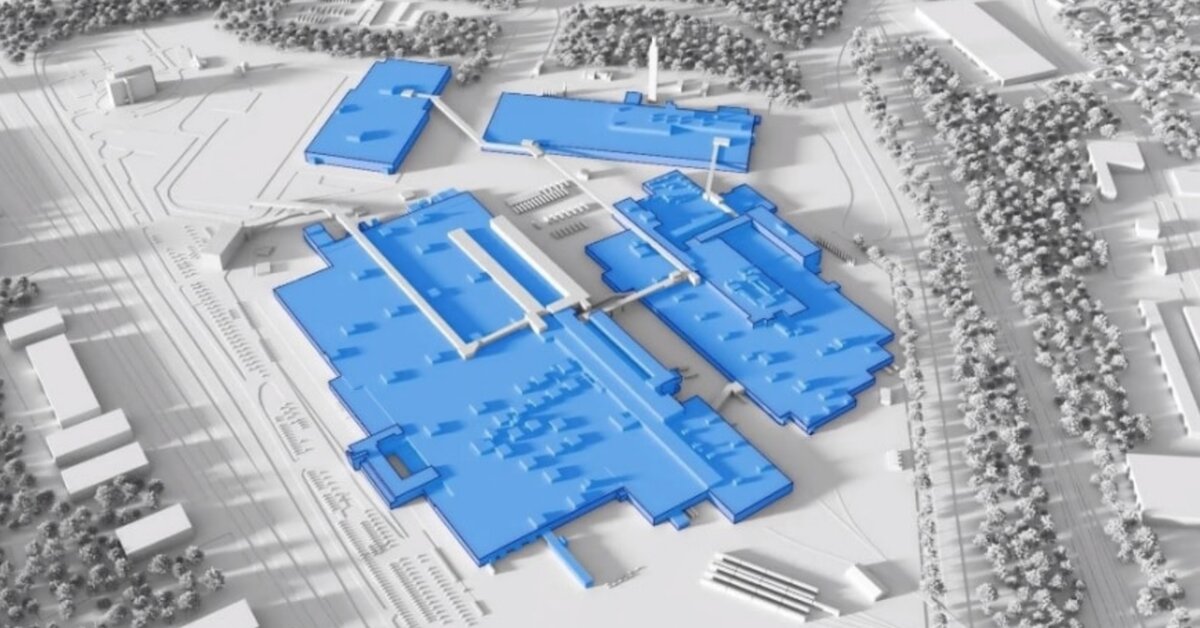

With the transformation of the Oakville facility into a high-volume hub for EV manufacturing, Ford plans to create a modern, super-efficient, vertically integrated site for battery and vehicle assembly. The new 407,000 square-foot on-site battery plant will utilize cells and arrays from BlueOval SK Battery Park in Kentucky, and Oakville workers will assemble battery packs that will then be installed in vehicles assembled on-site.

This investment is expected to create around 3,000 new jobs in Canada, with the majority of these jobs being in the manufacturing sector. In addition, Ford’s investment will likely have a positive impact on the Canadian economy as a whole. The automotive industry is one of the largest contributors to Canada’s GDP, accounting for nearly 10% of the country’s total exports. By investing in the Oakville facility, Ford is helping to ensure the continued growth and success of the Canadian auto industry.

Battery Production and Assembly

As part of the transformation of the Oakville Assembly Complex into the Oakville Electric Vehicle Complex, Ford will be building a new 407,000-square-foot on-site battery plant that will be used to produce batteries for the next-generation electric vehicles manufactured at the facility. The batteries produced will be made using cells and arrays sourced from BlueOval SK Battery Park in Kentucky, which is a joint venture between Ford and SK Innovation.

At the Oakville Electric Vehicle Complex, workers will take the battery components produced at the Kentucky plant and assemble them into battery packs. These battery packs will then be installed in the electric vehicles that are being assembled on-site. This vertical integration of battery production and vehicle assembly will allow for greater efficiency and cost savings, as well as tighter control over quality and supply chain management.

The Oakville Electric Vehicle Complex will be the first facility of its kind to produce electric vehicles for the North American market, and its battery production capabilities will play a key role in achieving Ford’s goal of producing more than 600,000 electric vehicles annually by 2023.

Conclusion

Ford’s investment of C$1.8 billion in the Oakville Assembly Complex represents a major step forward in the company’s commitment to electric vehicle production and sustainability. The transformation of the complex into the Oakville Electric Vehicle Complex, complete with a new battery plant and integrated vehicle assembly, will position Ford as a leader in the growing electric vehicle market in North America. By investing in a sustainable future and creating new jobs and opportunities for Canadians, Ford is demonstrating its commitment to innovation, environmental responsibility, and economic growth. With the Oakville Electric Vehicle Complex set to begin production of next-generation electric vehicles in 2025, the future of Ford looks bright.